Plasma spraying

Spraying with high energy

The coating material (powder) is introduced by means of carrier gas into a plasma jet, melted and deposited on the prepared surface.

The plasma jet is generated by a centrally disposed electrode (cathode), an annular nozzle (anode) and a dissociating and ionizing plasma gas.

As plasma gases may be used: hydrogen, nitrogen, argon or helium.

Areas / benefits

- Plasma spraying is suitable for the processing of refractory metals, oxides, carbides, borides, etc.

- Applications: Aerospace (e.g. turbine blades and inlet areas), medical technology (implants), thermal barrier coatings

Typical materials

Metals: molybdenum, chromium steel, Ni-Cr steel etc.

Ceramics: Al2O3, Al2O3/TiO2; Cr2O3, Cr2O3/TiO2

For more information, see materials.

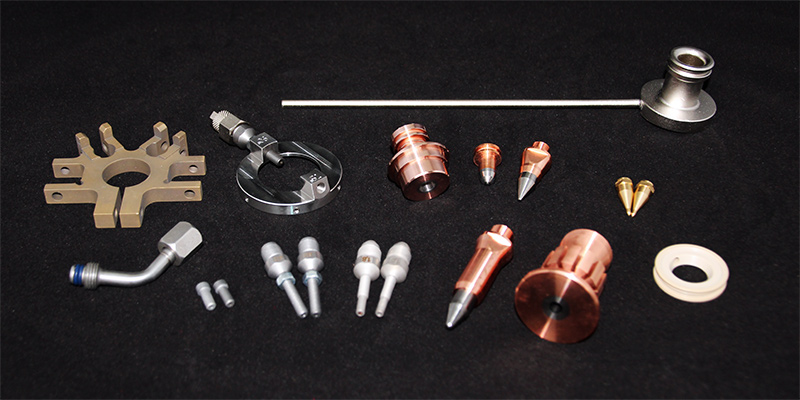

Spare Parts, components

Electrodes & plasma jets with and without tungsten core, water power hoses available in all lengths and with all the connecting threads, powder injectors, gas rings, powder tubes, adapter, universal adapter for powder hose connections, powder hoses by the meter.

Set of seals (“l” and “H”) for powder feeder MFP

The MFP powder conveyor is still in use at many thermal spray operations. However, the procurement of spare parts is becoming increasingly difficult. Due to many customer requests for the seal sets “L” and “H”, we have decided to offer an alternative for this. Successfully. The feedback from our customers is very positive. Consequently, the “L” and “H” seal sets for the MFP powder feeder are now part of our delivery range.

Are you also interested? Then please feel free to ask us.