Arc spraying

An universal and inexpensive method

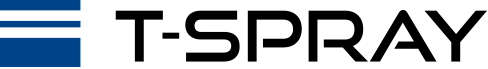

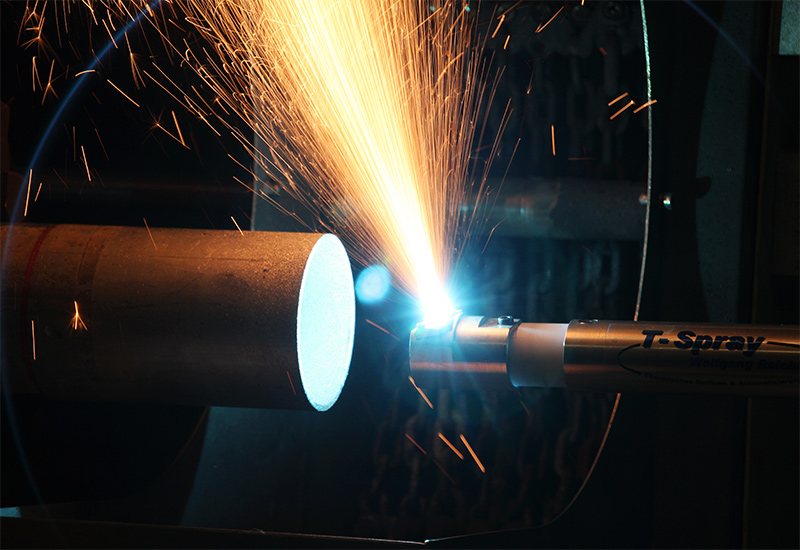

In arc spraying, an arc is ignited between two electrically conductive wires.

The coating material is present as a wire. The wire is melted by the arc. The material is applied by means of atomizing gas on the surface. Because of the high mass of particles of the coating material the particles impinge with high thermal and kinetic energy to the surface and micro-weld together with the surface. Thereby a good adhesion is achieved.

Areas / benefits

- Large-scale coatings that require high performance spraying

- Coatings with several millimeters thickness can be realized

- Good deposition rate and excellent adhesion

- Applications in which the autogenous flame is undesirable as an additional heat source, such as in the coating of plastic or paper

- Various possibilities of finishing: turning, milling, grinding, etc.

- “Solderable” coatings are possible

- Particularly user-friendly: the spraying process starts and stops instantly. For ease of use: the injection process starts and stops instantly. Neither energy nor material be used more than necessary.

- Very economical method with high availability and low energy and material costs.

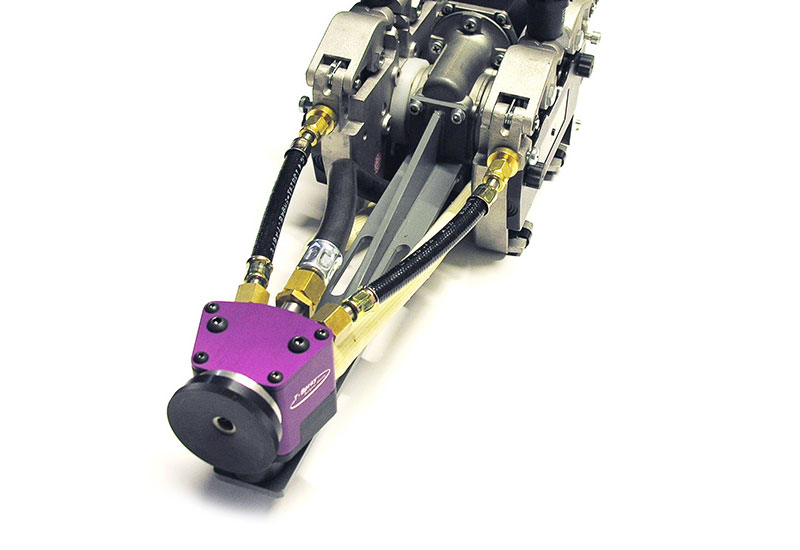

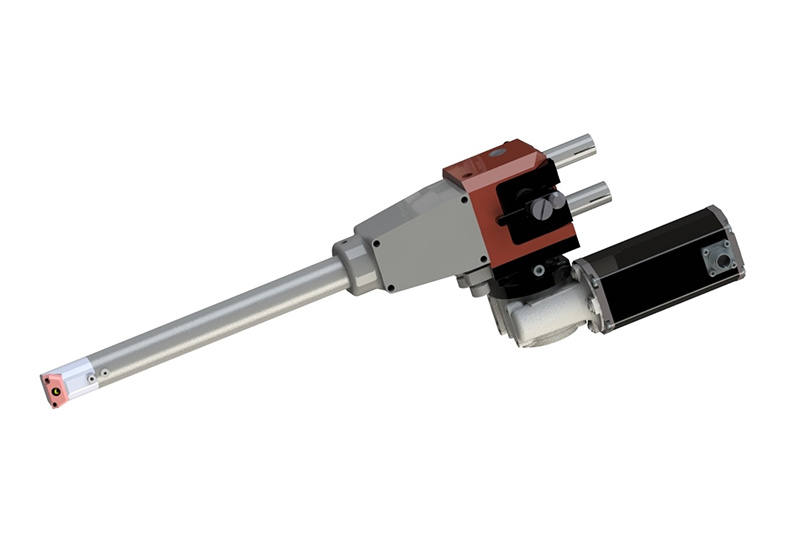

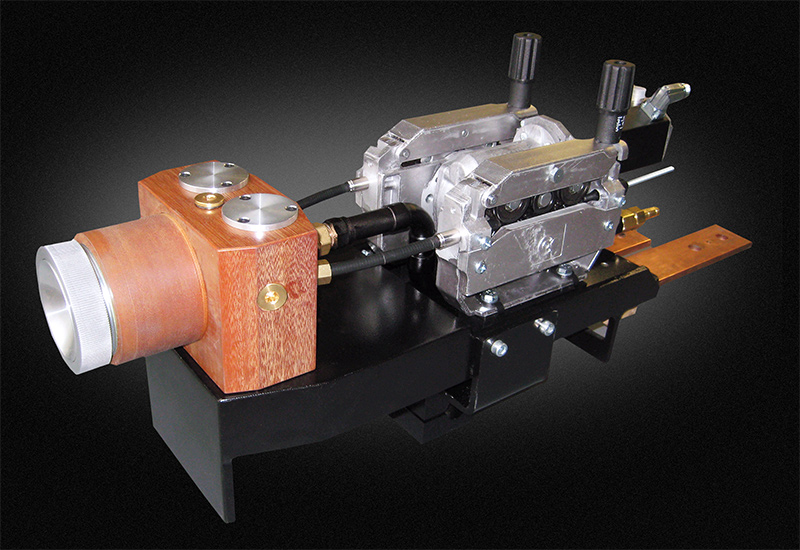

Our arc spraying guns

Typical materials

NiAl 95/5, NiCr 80/20, NiTi 96/4, AlBz8, CuSn6, 13% Cr, 19% Cr, 29% Cr, Zn, Inconel 625,

Cored wire (seamless and seamed)

For more information, see materials.

Spare Parts, components

Electrodes, nozzle discs, wire feeder, wire unwinding systems, LD/U-2, antiCOR