Flame spraying

The classic among thermal spraying processes

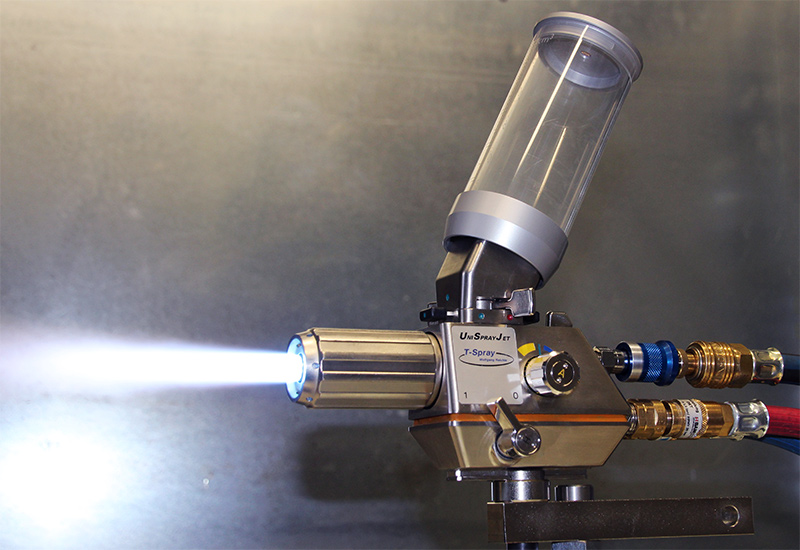

The flame spraying process is one of the oldest thermal spraying processes. In this method, the coating material is used either as wire or powder. By the oxy-acetylene flame, the material is melted and applied by the atomizing gas to the surface.

Areas / benefits

- Simple coatings with relatively high porosity can be applied

- The coatings can usually be finished by turning and/or grinding

- Flame spraying is a simple spraying method

Typical materials

Wire materials: molybdenum, Cr steel, Ni-Cr steel, Zn, CuSn, AlBz etc.

Powder materials: metals (Cr steel, Cr-Ni steel, NiAlMo, NiCrBSi, Zn, CuSn, AlBz etc.), ceramic (Al2O3, Al2O3/TiO2; Cr2O3, Cr2O3/TiO2, Cr2O3/SiO2/TiO2), plastic (PA, nylon)

For more information, see materials.

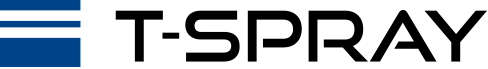

Wire flame spraying

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers. More Information

Powder flame spraying

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers. More Information

Spare Parts, components

Nozzles, nozzle nuts, air caps, siphon plugs, wire feeder etc. for all systems (e.g. 11E, 12E, 14E, 5K, UniSprayJet).

For older systems (e.g. 10E) spare parts can also be supplied.

Extension 5XT-T-spray – developed in a more stable version with better air seal for gun systems such as 12E and 5K.

Fluxmeter, connection systems (hoses), uncoiling systems, powder feeder systems